What Is UV Printing ? Know Its Process and Advantages

Thinking of using UV printing? Read on to learn about its working process, benefits, drawbacks, and more to determine whether it is the right one for you.

UV printing is a revolutionary printing technology that has made commercial printing easy and faster. The durable, vibrant, and high-quality prints made it popular in almost every sector, from packaging to the textile industry.

In this article, we will explore UV printing in detail and share insight regarding its working process, key components, benefits, drawbacks, and many more!

What is UV printing?

UV printing, also known as ultraviolet printing, is a digital printing technique where special UV-curing ink is used to print on the surface of materials (substrate). When the UV-curing ink is exposed to ultraviolet (UV) light, a photochemical reaction occurs, because of which the ink dries out instantly.

As long as the material fits the printer, this printing technique can be used to print on almost any material, including paper, plastic, acrylic, glass, foam board, wood, aluminum, and so on.

History of UV printing process

The history of the invention of the UV printing process can be traced back to the early 1970s. During that time, UV inkjet printing technology was used to print bar coding, direct mail, and labeling on the packaging, usually on flat surfaces.

Besides, UV inkjet printing was both expensive and time-consuming.

Later, in the mid-2000s, the development of UV-curing gel nail polish technology laid the groundwork for UV printing technology in the printing industry. The fast-drying, long-lasting, flawless result of a manicure brought to light the benefits of UV ink-curing. Eventually, UV printing technology began its journey in the printing industry for commercial and industrial applications, and it has grown in popularity ever since.

How does UV printing work?

The UV printing technology is an automated process. All you need to do is select the design, set your material, and send the command to the machine. The special type of ink will flow through the nozzles of the printhead and fall on the surface of the materials.

The printhead keeps moving back and forth, because of which the high-intensity UV light that is present beside the nozzles falls on the ink almost immediately and dries the ink instantly.

What are the key components of a UV printing machine?

Let’s take a look at the main components of a UV printing machine.

Printheads

The printheads are the primary component responsible for creating patterns and ensuring image quality. It is made up of numerous tiny nozzles through which ink is dropped on the surface of the substrate. The printhead’s speed, accuracy, and stability determine the precision of the prints.

Therefore, when choosing a UV printing machine, make sure to go for top-of-the-line printhead brands so that you can be assured of their quality and efficiency.

Note: High-quality printheads guarantee excellent image quality.

PCB (Printed Circuit Board)

The PCB (Printed Circuit Board) is another key component that serves as the brain of the UV printing machine. This device ensures smooth operation by controlling the actions of all the parts involved in printing, such as the printheads, motors, light sources, sensors, and so on.

A high-quality circuit board regulates the flow of the electrical signals within the different components of the machine and ensures synchronization of critical parameters such as ink flow, timing, curing process, etc.

So, make sure the PCB has durable wiring and an effective heat dissipation system. This will keep the PCB from burning and give it a long life.

Curing light

The curing light is the star component of the UV printing machine. The curing light consists of an LED UV lamp that dries out the ink. The machine uses a unique type of ink that has a dual state that allows it to remain liquid under normal circumstances and change to a solid under an LED UV lamp.

In the past, mercury lamps were used as curing lamps. However, today the mercury lamp has been replaced by the LED lamp because it has a longer life and is more energy efficient.

Machine Body

The machine body is the foundational component, as all other components are assembled within it. The structure of the machine body varies depending on the type of UV printing machine.

The following are the types of UV printing machines:

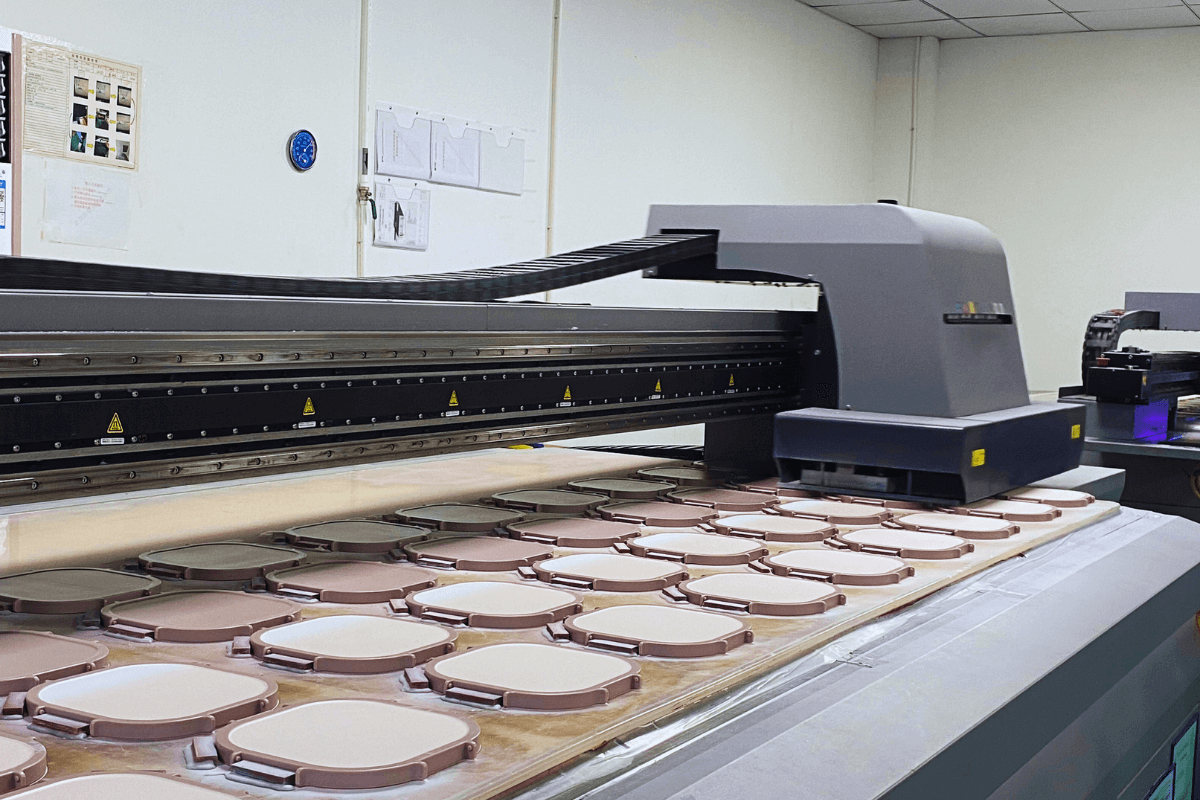

● Flatbed UV printing machine: The body of this type of UV printer has a flat surface. Materials such as paper, envelopes, cards, etc., are placed on that surface for printing.

● Roll-to-Roll UV printing machine: This type of UV printer has wide rollers. Flexible materials such as canvas, fabric, etc., goes through the roller to get printed.

● Rotary UV printing machine: This type of UV printer has a chamber where cylindrical materials such as bottles, cans, jars, and so on can be placed. The materials keep rotating while the printing process takes place.

The quality of the printing depends highly on the machine body. A stable machine ensures precise printing by preventing machine failure issues such as shaking, errors, or other operational problems that compromise printing quality. Moreover, a high-quality machine body has a significant impact on the overall performance of the machine.

Guide Rail

A guide rail is another essential component that allows the carriage to move back and forth during printing. The guide rail helps the printhead carriage and other printing elements maintain a precise position and movement while printing.

To ensure the positional accuracy of the UV flatbed printer, CN CROWN uses high precision UV printing equipment and incorporates an advanced motion system in the equipment control system. This system monitors and controls the printhead movement in real time by installing sensors on the guide rails that send signals to the press control system.

It works by maintaining the stability of the printhead while minimizing vibration to achieve clear, high-quality printing results. Its high-precision features result in errors of less than 0.02 mm and 0.01 mm, respectively, ensuring precise positioning and meticulous control to print with superior accuracy and quality.

How to achieve the production of UV printed finished products?

Printing with a UV printer is an easy task; however, there are certain steps that must be taken into consideration to achieve high-quality prints. Let’s learn the step-by-step process to achieve the production of UV-printed finished products.

1. Drafting Methods (Choosing different drafting methods based on different materials)

The first step is to decide on drafting methods based on the characteristics of the materials you intend to print. The drafting technique includes the selection of the production process and the design drawing.

Each material has unique surface characteristics and therefore requires a different type of surface treatment. For example, the surface of paper can be rough, smooth, glossy or matte. And in the case of food container materials, such as PP materials, the surface has the property of being self-oiled.

However, to ensure that the printed design stays attached, the surface of the PP material must be properly treated prior to printing to meet the required adhesion requirements. Although this may result in some minor marks on the surface, CN CROWN can largely conceal these marks by using the proper treatment to create a perfect design pattern.

2. According to the design drawings, objects to produce printed manuscripts (the pattern needs to be converted once before printing)

Before beginning the actual printing process, the chosen design or pattern should be printed on the materials for testing purposes. The draft or manuscript will give you an idea of whether the designs will be perfectly printed on the surface or whether you need to make adjustments to your design, such as re-formatting or resizing.

Since the quality of the prints varies depending on the materials, it’s best to create manuscripts so that you can be sure of how the final product will look on your selected materials.

3. Select the adapted positioning frame

The next step is positioning the frame. The positioning frame, also known as the positioning plate, is a frame on the printer’s workbench that holds the printing material in place while printing. Properly adjusting the positioning frame will keep the material in a fixed position and help maintain a consistent alignment throughout the printing process.

The size, dimensions, and shape of your materials should be taken into consideration when selecting the appropriate positioning frame. The proper placement of your materials inside the positioning frame will help you ensure the image or prints fall in the exact position you intended.

4. High-precision equipment for perfect printing patterns

Now comes the most important step, which is to select high-precision equipment. The quality of the prints mostly depends on the quality of the equipment. The flow of the ink, movement of the printhead, and function of other components all together produce a flawless print with fine details.

At CN CROWN, we use the most advanced and mainstream equipment on the market to ensure a high degree of precision and perfect printed patterns.

Advantages

UV printing technology offers a number of benefits over other types of printing methods. Let’s check out the advantages you can get from the UV printing technique.

1. Color diversity selection

The greatest advantage of using UV printing technology is the availability of a wide range of colors. UV printers have an advanced color management system that allows for color customization from seven different colors: C, M, Y, K, LC, LM, and W.

Unlike the traditional printing technique that used to mix color manually from only four colors (C, M, Y, and K), UV printers can automatically identify color mixing through the equipment and support printing up to 30 or more colors at once. Therefore, you can enjoy the versatility of using different shades to create vibrant prints with UV printing.

2. Printheads (the higher the precision, the more perfect the printed pattern)

Higher accuracy of the printheads gives the UV printers an upper hand. Although there are various printheads available on the market, their precision quality is not the same. CN CROWN prefers using the G5i and G6 printheads, which are popular for their superior accuracy and reliability. The printing of minute details, vivid colors, and delicate to complex patterns is all possible with these printheads.

3. High production efficiency, simple operation, fast sample making

UV Printing offers higher production efficiency. The instant drying of the ink accelerates the production speed. As a result, a bulk amount of printing can be completed within a short period of time with better printing quality compared to traditional printing technology.

Furthermore, the user-friendly design of UV printers makes machine operation simple. The straightforward software interface, automated features, and user-friendly controls require minimal training. You can create samples faster and make the required adjustments for the final production without wasting hours.

4. Safety

Operating a UV printer is safe for both the operator and the environment. The raw materials used in the UV curing ink have passed the food contact level test. Besides, the instant drying of the ink prevents the release of VOCs, toxic fumes, or ozone into the atmosphere and leaves little to no carbon footprint. And to ensure operational safety, operators wear anti-UV glasses to protect their eyes.

Disadvantages

Every printing technique has drawbacks, and UV printing is no exception. One of the significant disadvantages of using UV printing is-Restricted print height

You have to maintain a strict distance of 2mm between the nozzle of your printhead and the surface of the material. This optimal distance will keep the nozzle close enough to the material to get precise prints while also keeping the material from coming into contact with the nozzle, which may damage both the material and the machine.

Applications

UV printing is in high demand for almost every industry, from signage and customized furniture to promotional items and packaging, due to its visually appealing features and long-lasting prints. Let’s look at which industries you can use UV printing.

Furniture industry

Wood, plywood, plastic, glass, and other materials are commonly used in the furniture industry. UV printers can be used to print customized patterns on tables, doors, closets, or other furniture.

Interior decoration industry

UV printing can also be used in the interior decoration industry. Different types of materials, such as wood, metal, glass, acrylic, etc., are used to elevate the visual aesthetics of houses or office spaces. UV printing can be used to create patterns, graphics, or imagery that can be used to decorate walls, ceilings, floors, photo frames, and other elements.

Packaging industry

The packaging industry requires visually appealing, vibrant printing of patterns, logos, texts, etc., in plastic, metal, or glass materials, such as beverage bottles, food packages, or cosmetic products. As UV printing supports almost every type of material and creates durable prints within a very short time, its demand is pretty high in this industry.

Electronic products industry

The electronic product industry mostly works with plastic to create the bodies of electronic devices. UV printing is used to print product information such as a logo, bar code, serial number, instruction label, warranty information, and so on for branding and to prevent counterfeiting. Various customized patterns and textures are also created to make the devices visually appealing to customers.

Automotive industry

UV printing is used in the automotive industry to print branding elements such as logos, names; personalized details like vehicle identification numbers, serial numbers; anti-Counterfeiting information like holographic codes, special codes; or warning signs, operating instructions, or safety-related information.

Textile industry

The textile industry uses UV printing technology to create patterns on clothing. The UV printing works well with a wide range of fabrics, including cotton, nylon, polyester, silk, and others. The UV-cured inks form a strong bond with fabrics. As a result, the prints and color vibrancy stay for a long time, even after repeated washing.

UV printing vs. screen printing: which is right for you

Although both UV printing and screen printing are used to print materials, they have different advantages and disadvantages, making one more advantageous than the other.

Let’s look at their features to see which one is best for you.

● It offers a wide range of color options.

● The ink dries instantly.

● It can be used to print almost every material.

● The prints are vibrant in color and have fine details.

● It can print flat, cylindrical, or flexible materials like fabric.

● It produces long-lasting results that are less likely to fade or be affected by weather.

So, which one do you think will be the right one for you?

Obviously, UV printing!

Conclusion

So far, we have discussed everything you need to know about UV printing, from what it is, how it became popular, its working process, different key components, benefits, drawbacks, applications, and many more!

Hope the above-mentioned information helped you learn about UV printing technology and help you decide whether it is the right one for you.

Related Posts

How To Pack Lunch For Work? 12 Tips for Packing Food with Ease

Busting your food budget? Want to bring lunch to work? Here are some of the most effective tips to help you figure out how to pack lunch for work. Do you know the secret to living a long and healthy life? It’s eating home-cooked meals! It's not only the key to a...

How To Successfully Develop and Produce Bento Boxes: From Idea To Market

Introduction Everyone around us is surrounded by carefully designed objects every day, including the bento boxes, lunch bags, cutlery, etc. that we use every day, all carefully designed by a person or team. From a creative idea to a commercial launch, this is what...

Healthy and Fun School Lunch Ideas: Best Lunch Containers and Accessories for Parents

Why Healthy and Fun Lunches Matter As parents, we often worry about providing nutritious meals for our children at lunchtime. But what some of us may not realize is that lunch is important for our little ones, too. Eating healthy and fun at school can have a positive...

0 Comments